We want to address recent concerns following the announcement that four additional marine terminal operators at the Ports of Los Angeles and Long Beach will suspend one PierPASS OffPeak shift per week. These suspensions are part of the process for marine terminal operators to continually adapt the number of OffPeak shifts to match fluctuations in cargo volume. The suspensions are a result of the traditional seasonal decline and should not cause further delays at the ports of Los Angeles and Long Beach. The MTOs will continue to address issues of congestion and closely monitor cargo volumes with the intention of returning to a fifth PierPASS OffPeak shift when cargo volumes warrant an additional shift. Please stay tuned to pierpass.org for additional updates.

Category Archives: News

Monitor Terminal Gate Lines in Real Time

Check out PierPASS’s updated live camera feeds showing different marine terminal gates at the Ports of Los Angeles and Long Beach.

The page has been updated with camer feeds for STS and GGS. Click on any of the images to see a larger view. Click refresh on the page to get updated live images from the terminal gates.

We continue to update the page with additional camera views from all terminals to help LMCs monitor congestion levels at the terminal gates.

The Port of Los Angeles Supports Upcoming Turn Time Study

We recently had the chance to catch up with Michael DiBernardo, Director of Business Development for the Port of Los Angeles. We asked Michael about the Port’s participation in the upcoming Turn Time Study, commissioned by The Truck Turn Time Stakeholder Group and conducted by Dr. Val Noronha of Digital Geographic Research Corporation to provide metrics for tracking and monitoring truck turn times.

Q: Why did you decide to contribute to funding for the turn time study?

A: We felt it was necessary to capture data that will provide facts on how long truck drivers are queuing outside terminal gates. The terminals have the data once a truck driver enters the facility, but we have no means of measuring the queue time from a certain point outside the terminal. We felt the turn time study would help provide that data.

Q: What is the goal of the turn time study?

A: For the Port of Los Angeles, the goal of the study is to receive factual data of truck queue times in order to accurately identify problems of congestion and/or bottlenecks at the port.

Q: Why is the study important for the community?

A: The turn time study is important to the trucking and cargo owner communities because it ensures that factual information about turn times is available. Currently, mainly anecdotal information is being communicated to cargo owners and the media.

Q: What solutions to truck congestion would be beneficial for the ports?

A: The Port of Los Angeles believes the following solutions will be beneficial for the ports:

- Spreading out truck traffic to avoid peak congestion at 5pm

- Implementing port-wide appointments that offer flexibility

- Offering flex work gate schedules and five off-peak gates, which is already being done at most terminals

- Ensuring trucking companies’ drivers continue to work after 11pm in order to maximize the off-peak gates

Q: What is the biggest misconception about turn times at the ports?

A: One of the biggest misconceptions is to assume that because one trucking company reports they experienced two or three hour turn times, all trucking companies are experiencing those delays. In general, turn times are much shorter than what has been reported by the media and the majority of companies are not experiencing these delays. It is true, however, that at certain hours of the day, turn times may be long due to trucks waiting for evening, or OffPeak, gates to open. Many trucks show up at the same time to take advantage of the OffPeak gate.

Q: How will the results from the study be used to generate possible solutions to truck congestion at the ports?

A: Following the conclusion of the study, the Truck Turn Time Stakeholder Group will analyze the results and determine the next steps in addressing any issues that may be identified by the study. We will continue to keep the community updated with our findings.

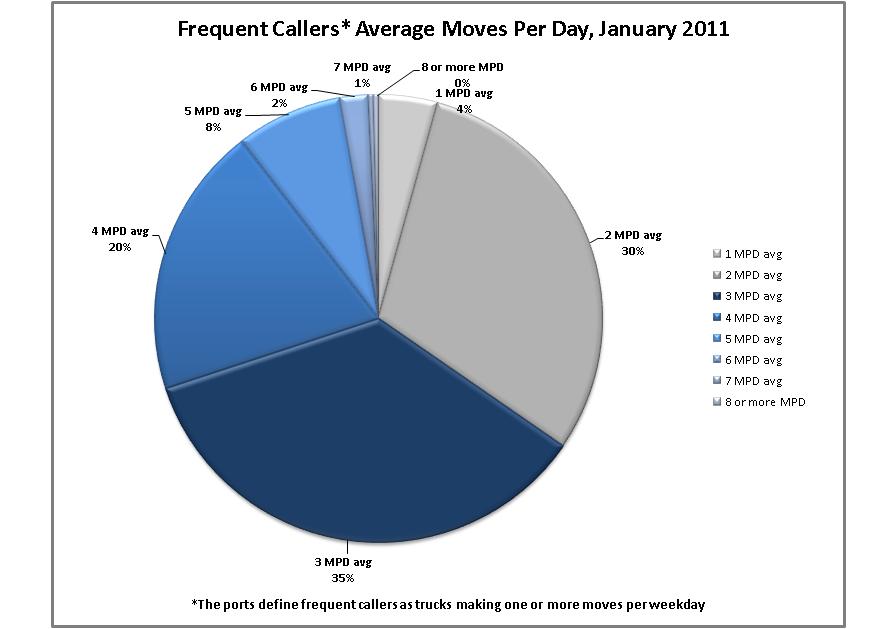

Among Daily Port Visitors, 66 Percent Make 3 or More Container Moves Per Day

The terminal operators and others are working to provide metrics for tracking port operations.

One important metric is the number of container moves trucks make per day. The data collected by PierPASS to run the OffPeak programs lets us see exactly how many moves each truck makes.

For the purposes of this analysis, we wanted to find out how many moves a truck makes if it is working every day. To do so, we looked at “frequent callers,” which the two ports define as trucks making one or more moves per weekday.

The data shows that 66 percent of trucks averaged three or more container moves per day in January 2011, compared to 81 percent in December 2010.

It is important to note that “moves per day” isn’t necessarily the same as “turns per day.” A turn, or round trip, can involve either one container move or two.

The terminal operators have begun reporting in-terminal turn times and are working on ways to track and report queue times outside the terminal gates. Stay tuned for more info soon.

PierPASS – Working Together to Combat Congestion at the Ports

[youtube=http://www.youtube.com/watch?v=fEVB2-7_3nM&hl=en&fs=1]

In 2011 the Ports of Los Angeles and Long Beach are operating at high efficiency. Watch how PierPASS has helped ease congestion in the Ports and continues to stress the importance of bringing the community together to maintain San Pedro as the country’s premier port.

Turn Time Study in Progress

The Truck Turn Time Stakeholder Group (a collaboration among PierPASS, LA/LB port terminal operators, motor carriers, shippers, and port authorities in Southern California) is pleased to announce that Dr. Val Noronha of Digital Geographic Research Corporation has been commissioned to conduct a study to provide metrics for tracking and monitoring truck turn times.

The study is based on METRIS technology, deployed at the ports with the support of the USDOT Research and Innovative Technology Administration and the University of California, Santa Barbara. It will examine GPS tracks from thousands of truck trips to the ports each month. It will measure time outside terminals, time inside terminals, and other aspects of truck fleet performance.

The study is jointly funded by PierPASS, Ability Tri-Modal, and the Ports of Los Angeles and Long Beach, and is expected to be complete in March.

According to Bruce Wargo, President of PierPASS, “This study is an important part of our commitment to working with all stakeholders to identify ways to track and report queue times and offer solutions based on factual information.”

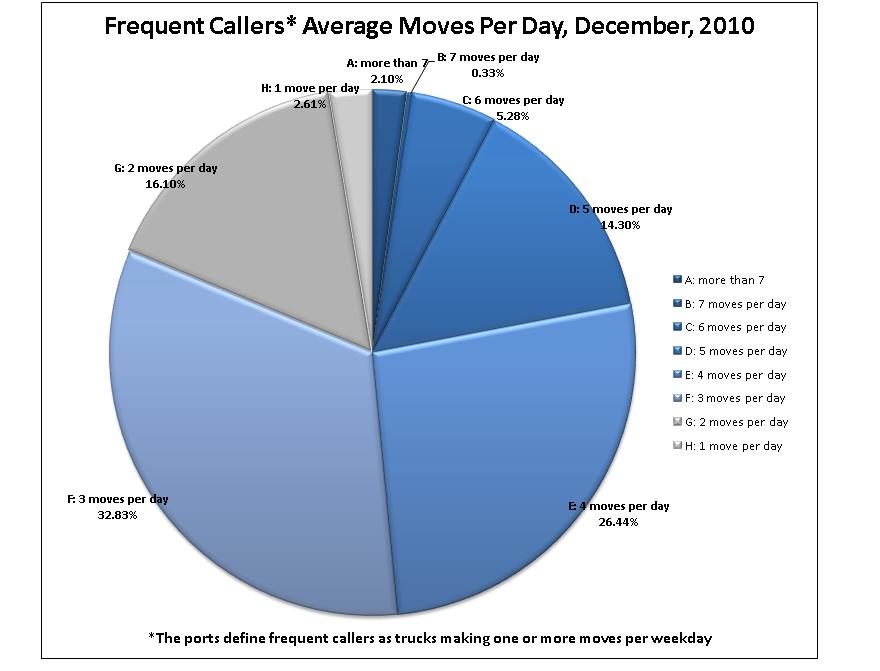

Among Daily Port Visitors, Nearly 50 Percent of Trucks Make 4 or More Container Moves Per Day

The terminal operators understand that turn times are an important issue for the truck community and are committed to working with the community to move cargo efficiently through the ports. Last summer, PierPASS formed a working group of 30 stakeholders representing importers, exporters, motor carriers, ports and marine terminal operators to address issues of congestion, including wait time outside terminal gates.

To be effective, this effort needs to be based on factual information. The terminal operators and others are working to provide metrics for tracking port operations.

One important metric is the number of container moves trucks make per day. The data collected by PierPASS to run the OffPeak programs lets us see exactly how many moves each truck makes.

For the purposes of this analysis, we wanted to find out how many moves a truck makes if it is working every day. To do so, we looked at “frequent callers,” which the two ports define as trucks making one or more moves per weekday.

The data shows that 81 percent of trucks averaged three or more container moves per day in December. Nearly half of trucks – 48.4 percent – made four or more moves per day. Twenty-two percent made five or more moves per day, and 2.4 percent averaged seven or more moves per day.

It is important to note that “moves per day” isn’t necessarily the same as “turns per day.” A turn, or round trip, can involve either one container move or two.

The terminal operators have begun reporting in-terminal turn times and are working on ways to track and report queue times outside the terminal gates. Stay tuned for more info soon.

TTI uses appointment system and RFID technology to manage turn times

We recently had the chance to catch up with Mark Milburn, General Manager Operations, Total Terminals International (TTI). We asked Mark about TTI’s mandatory appointment system, which they have used for years, as well as other recent measures they have done to handle increased cargo volumes.

Q: What have you done to handle increased traffic?

A: TTI has used flex shifts during meal hours and before the start of the OffPeak gate to process a consistent 100+ empty containers per flex shift into the terminal and to prevent long lines for truckers. Shift start-ups at TTI have been consistently absent of truckers lined up on the street.

TTI and many of the MTOs hire additional ILWU labor each shift to fill in open positions for all labor categories during the coffee break periods to ensure all yard equipment is available to continually process truckers. Increasing the labor each shift lowers overall turn times, yard and gate congestion and delays for the trucking community, and ensures delivery schedules to warehouses can be met more consistently.

Q: TTI has used a mandatory appointment system for several years. What benefit does this system provide to customers and TTI?

A: The appointment system assists in reducing gate and yard congestion by controlling the number of truckers arriving each hour at the terminal gate. This prevents the situation of trucks bunched up in the first three to four hours of a shift and then virtually no traffic in the second half of the shift.

The appointment system helps us use the full eight-hour shift to service truckers to ensure faster turn times with virtually no congestion.

Q: How does the appointment system handle mandated coffee break period and meal hour breaks?

A: All MTOs have to comply with the existing ILWU labor contract, which includes a mandatory one-hour meal break taken mid-shift and two quarter-hour coffee break periods, one before the meal hour break and one after the meal hour break.

During the meal hour shift, labor is reduced to comply with the meal break requirement. During this time, half of the labor takes an early lunch and the other half takes a late lunch. Although there is less equipment in use, truckers are still serviced in a timely manner and can meet deadlines. We accomplish this by using the appointment system to reduce the volume of trucks scheduled to arrive during the meal break.

Q: What other measures have you implemented to ensure that terminal congestion is not an issue in 2011?

A: TTI continues to tweak and modify the use of the appointment system for all import and export loads. The data collected over the years since we implemented a mandatory export and import appointment system puts TTI in a better position to order an accurate amount of labor to meet the needs for each shift. This translates into lower than normal trucker turn times at the gate and in the yard.

Q: How much would cargo volume have to grow before you would be unable to service the demand within your existing 10 shifts per week?

A: Past historical data shows TTI would be able to sustain a substantial container volume increase in 2011 and still be capable of servicing our customers in a timely manner within the 10 shifts. As in the past, additional equipment and labor would be increased to match the anticipated volume.

Q: Have you made or are you making any substantial new infrastructure investments that you can talk about? What is the intended benefit of the investment?

A: TTI recently installed radio frequency identification (RFID) readers on the main roadway coming into the terminal’s gate area (Hanjin Road, Pier T). This provides an accurate measurement of the time a truck takes to get from point “A” to point “B” just before they enter the terminal gate to be serviced (the distance measured on the street before entering the gate area at the terminal is a half mile). This new tool will provide street dwell time data to enable TTI to accurately monitor the truck volume throughout the 10 working shifts and ensure labor is available during peak traffic times to prevent congestion and idle time outside the terminal gates.

Signs of Hope: Record Export Volumes at the Port Of Los Angeles for 2010

Yesterday, the Port of Los Angeles issued a press release with optimistic news: year-over-year container traffic surged 16% in 2010, led by an all-time record of exports. Exports at the Port of Los Angeles rose 10.3 percent over 2009, while imports rose 12.8 percent. The rebound we witnessed in 2010 is an encouraging sign of recovery. It shows that the Ports of LA and Long Beach are putting people back to work and is good news not only for the goods movement industry and the local economy, but the country as a whole.

A quick look into recent history and record volumes: 2008 was the previous record year for exports at POLA, with 1,782,502 TEUs. This is now surpassed by 2010 with 1,841,274 TEUs, up 3%. On the other hand, imports are still 11% below the record year of 2007, when POLA imports hit 4,410,169 TEUs, compared to 3,973,933 TEUs in 2010. Our hope is that this momentum will continue into 2011, and translate into record volumes for the import business in 2011.

The marine terminal operators in LA/Long Beach are continuing to work with key industry stakeholders to ease the challenges of increased cargo volume, improve the efficiency of cargo movement and help the industry take advantage of unused capacity to minimize congestion.

We’re encouraged by the gains at the ports and look forward to an update from the Port of Long Beach for the last month of 2010. Stay tuned for more updates on cargo volumes.

Q & A with John Ochs, APM Terminals

We recently had the chance to catch up with John Ochs – Managing Director, APM Terminals Pier 400, which handles approximately 1.6 million TEU and is the largest single proprietary terminal in the world. With a total of 484 acres, APM can accommodate 8,000 wheeled and 17,000 grounded containers.

We asked John about Pier 400’s recently rolled out appointment system, how things have been going for APM this year and how 2011 is looking for the terminals at the Ports of Los Angeles and Long Beach.

Here’s what he had to say:

PierPASS: Why did you decide to roll out an appointment system earlier this year at Pier 400?

John: The TermPoint system allows us to better understand what volume of drayage truckers to expect on any given shift. We can then adjust our labor order to provide the appropriate number of equipment operators to service the truckers. Additionally, an appointment system allows us to distribute the volume of drivers throughout the entire shift. The result is a reduction of queue time, as there is not a surge of truckers attempting to get serviced at the start of the shift.

PierPASS: How does the appointment system work and how does it affect the truckers coming through your terminal?

John: The system allows trucking companies to make appointments once containers are discharged. The effect on the trucking community is the need to monitor their containers and plan their deliveries to ensure they secure appointment times that best meet their business needs. Our system has been well received by the trucking community and, since the implementation, our data has shown reduced turntimes, which is a huge benefit to truckers using Pier 400.

PierPASS: How will the appointment system increase efficiency at APM?

John: Again, the appointment system provides us the visibility of what volume/activity to expect. The system also provides us the ability to know where to position our CHE (container handling equipment), therefore providing efficient and timely service throughout the shift.

PierPASS: What other measures have you implemented this year to handle increased traffic in your terminal?

John: We have reallocated the use of our truck gates to better segregate truck traffic for import and exports.

PierPASS: What is your outlook for 2011?

John: The cargo volume forecast for the first quarter is relatively stable, and Chinese New Year is early this year. The entire industry is awaiting the forecast for the second quarter with great anticipation.